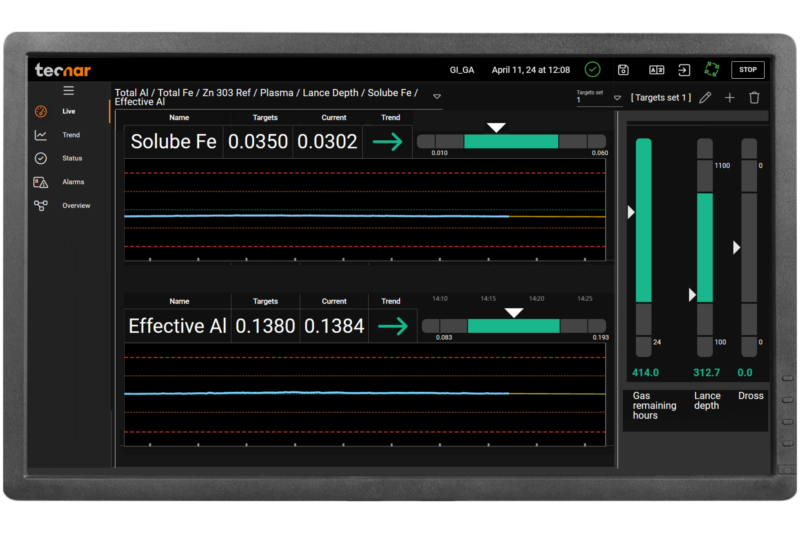

Molten metal bath chemistry analyzer for continuous hot-dip galvanizing lines

The Galvalibs 2.0 is the only true multi-element, online, real-time and accurate bath composition analyzer.

Talk to an expertBath composition analyzer advantage

Galvanizing is a balancing act of several elements in molten metal bath composition. Good chemistry management yields higher quality, more valued products.

Multi-element analyzer

The Galvalibs 2.0 is the only online multi-element analyzer for bath management:

- Effective aluminum

- Dissolved iron

- Magnesium level

- Silicon concentration

Whatever your process, the Galvalibs 2.0 provides information on all the elements you need to track. Why limit yourself to one element when you can benefit from so many more?

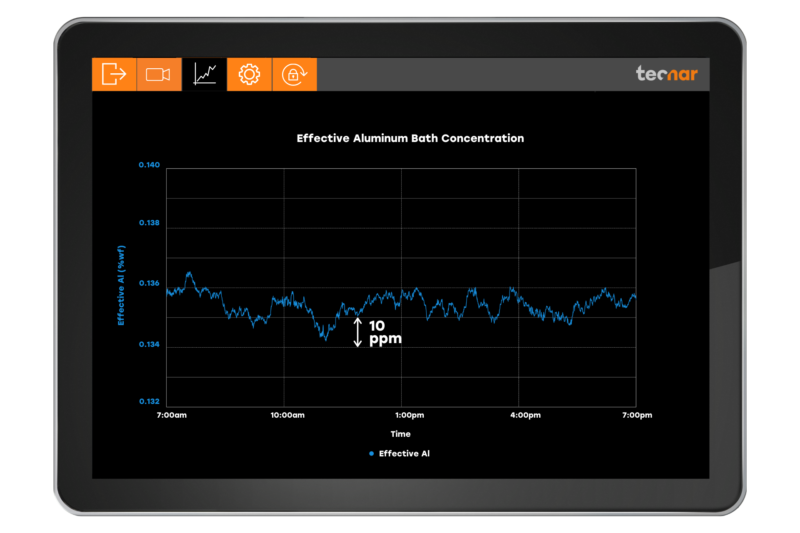

Proven high accuracy

The Galvalibs 2.0 yield real-time concentration measurements with a proven accuracy of 0.5% (RSD). With the Galvalibs, laboratory-level accuracy is now available in real time and online.

Want proof? Take a look at the concentration of dissolved aluminum in the Galvalibs measurements (blue curve) during a stable run. The scale of the display is 10 ppm per step. Sensitivity below 2 ppm is clearly seen.

The Galvalibs directly measures the composition of the liquid bath. It doesn’t require any temperature or phase-diagram-based model for calculation. That’s why the Galvalibs is the only true high-accuracy bath chemistry analyzer.

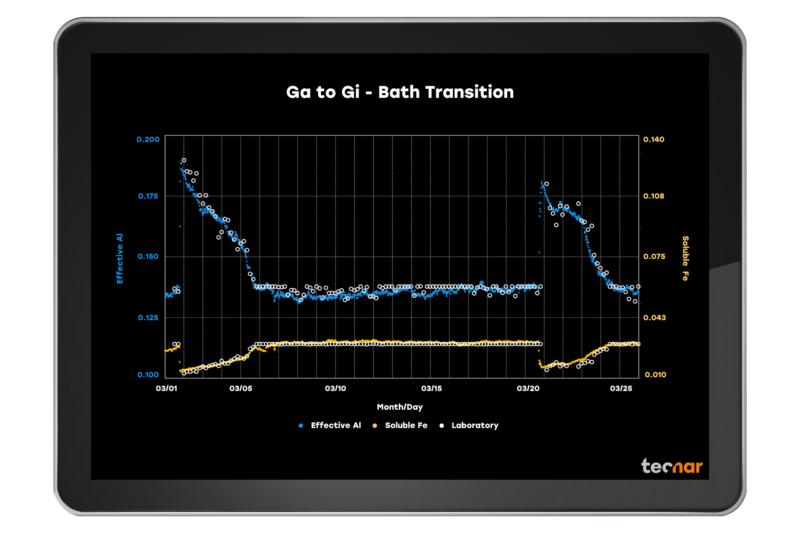

Data you can trust

The Galvalibs 2.0 is an industrial-grade, high-accuracy analyzer, specifically designed for harsh environments. Its proven stability drift of <1%/month is unequalled for online LIBS analyzers. What’s more, the quality of the Galvalibs 2.0 data is continuously monitored so you know you can trust it.

To prove it, we’ve collected bath samples every four hours for 25 days and compared laboratory analysis (circle) with real-time Galvalibs 2.0 measurements (blue for aluminum and yellow for iron). The match is quite remarkable with no recalibration during the entire 25-day cycle. Imagine the savings from reduced bath sampling with Galvalibs’ continuous reliable data.

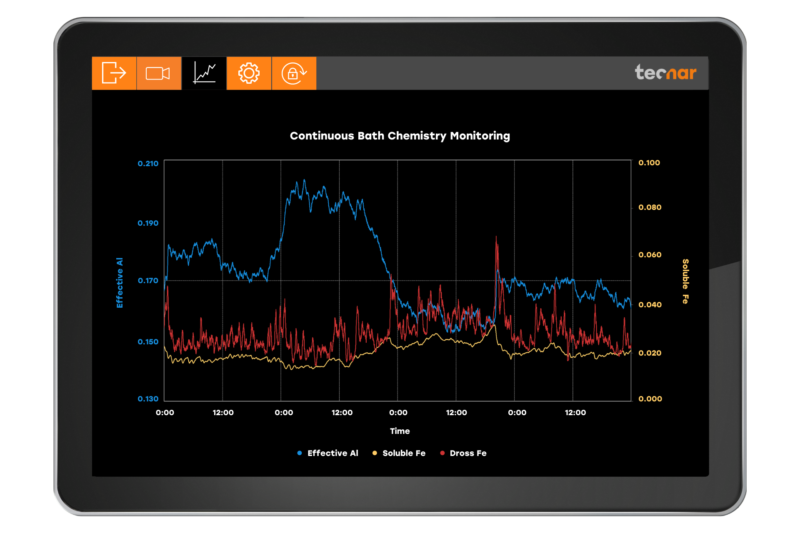

Continuous data

Production in a continuous galvanizing line never stops, so why rely on discrete data taken from time to time? Do you really know what’s happening between your sampling? The Galvalibs 2.0 provides continuous real-time data with no gaps in information. So you know what’s in your bath, all the time, every time.

Multiple processes

Agile production is the key to the modern galvanizing line, where quickly switching production processes is critical. Based on high-precision, laser-based technology, the Galvalibs 2.0 can switch from galvanized to Zn-Al-Mg to aluminizing with the touch of a button. The Galvalibs 2.0 is compatible with:

- Galvanize

- Galvanneal

- Galvalume

- Aluminum-Silicon

- Zinc-Aluminum-Magnesium

How it works

Interested in getting into real-time bath composition, dross and level control?

Our team will answer all your questions and suggest the best solution for your needs.

Leave your details so our experts can contact you.