Galvalibs 2.0

Monitors the dross level of the galvanizing bath in real-time

The Galvalibs 2.0 is the only online analyzer that continuously monitors the dross level in suspension in the bath, independent of bath chemistry and temperature.

Talk to an expertCreate the conditions for better dross control

The Galvalibs 2.0 is the new method to directly monitor the dross level of a galvanizing bath. The old way involves manually sampling the bath, followed by laboratory analysis and model-based corrections. Getting a good, consistent sample from the depths of the bath, without contamination from floating dross, is already a challenge.

What’s more, laboratory results must be corrected with temperature-dependent solubility models, so the traditional method may produce uncertain or unreliable results. The Galvalibs 2.0 provides a continuous automatic value of the dross level in suspension. No need for temperature correction. No need for bath sampling.

The bath cleanliness analyzer you can count on

The Galvalibs 2.0 displays reliable, continuous monitoring of the dross level. Evolution and trends are clearly observed since there are no blind zones and no time lag typically encountered with periodic manual sampling and processing. That means that operators can relate an unexpected rise in the dross level to plant events or activities, such as residual iron fines or bath temperature instabilities.

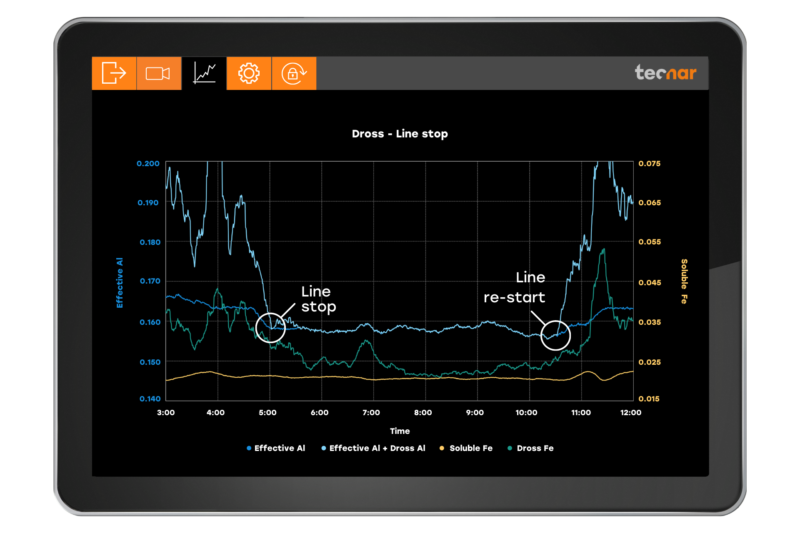

Data you can believe — line stop

The Galvalibs 2.0 monitors the dross level in suspension in the bath. When a line is stopped, there’s no turbulence in the bath and the dross slowly drifts to the surface or the bottom with very little dross in suspension. The first circle in the figure shows the time when a galvanizing line was stopped, while the second circle indicates the time when the line was restarted. The dross measurement quickly drops to zero when the line is stopped and slowly rises when the line is restarted, clearly demonstrating the Galvalibs’ sensitivity to dross levels.

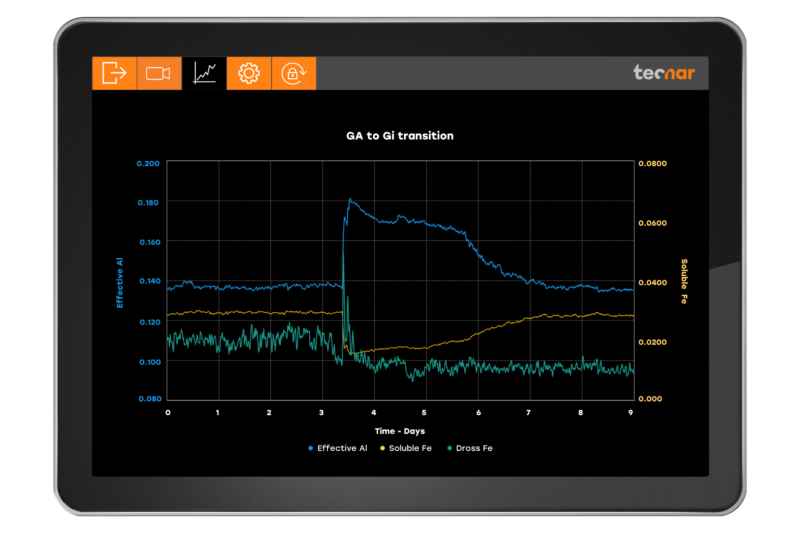

Cleaning cycle — Ga to GI transition

The galvanneal process produces a high level of bottom dross (heavy particles) as residue. Periodically, a galvanneal bath needs to be cleaned by adding a large amount of aluminum. Bottom dross is then transformed into top dross, which is removed by skimming. As the dross migrates from the bottom to the surface, the Galvalibs 2.0 can see the passing dross in suspension (see figure). Once the transformation of bottom-to-top dross is completed, the recorded dross level reverts to normal. Operators can use this information to easily determine when the transformation process has been completed.

See the impact of temperature swings

Dross is caused by an excessive Fe pushed into the bath during the steel and molten metal’s surface reaction when they enter the bath. Since Fe is continuously above saturation levels, rapid local temperature changes in the bath will play an important role in dross formation.

How it works

How does Galvalibs 2.0 directly measure the level of dross in the bath?

What is Laser-Induced Breakdown Spectroscopy (LIBS)?

Interested in getting into real-time bath composition, dross and level control?

Our team will answer all your questions and suggest the best solution for your needs.

Leave your details so our experts can contact you.